Inspections of energy plants

For safe, uninterrupted operation of renewable energy plants

Tested safety for employees and plants

ENERTRAG Operation’s technical services team consists of more than 30 employees at various locations in Germany. These experts specialise in various areas of testing: Machine inspections, gearbox and rotor blade inspections, vibration measurements and also DGUV-V3 inspections are all part of the range of services.

The services of the inspection centre begin with the initial commissioning of the wind turbine and accompany it through all phases of operation. Inspections and tests are carried out professionally and with the highest level of technical expertise. In this way, ENERTRAG Operation ensures a consistently high standard of quality and achieves complete customer satisfaction. Accreditation in accordance with DIN EN ISO/IEC 17020 clearly underlines this commitment to high standards.

Advantages

- Accreditation

Inspections according to accredited procedures since 2015: Clients work with qualified experts and fulfil their due diligence. - Certification

Continuous process optimisation according to ISO standards - Smart processes

Faster, simpler processes with the Powersystem inspection app for machine inspections. - Cost savings

Reduction of redundant inspections through comparable inspection processes. - Many years of experience

More than 20 years of experience as an operator and inspection centre with its own specialist staff. - Decentralised locations

Multiple locations across Germany and beyond. Optimised route planning enables capped flat rates for service charges.

Accredited inspections

Machine tests

Periodic inspection (WKP)

Periodic inspections are mandatory as part of the authorisation requirements. The aim is to recognise potential damage and eliminate any hazards posed by the wind turbine. They must be carried out at regular intervals by experts on the machine and rotor blades as well as on the supporting structure (tower and accessible areas of the foundations). The inspection intervals are specified in the expert reports on the turbine.

ENERTRAG Operation have the highest quality standards, as work on wind turbines requires the utmost care. Regular inspections and tests make the technical risk of wind turbines manageable and repairs can be planned for the long term - guaranteeing high energy availability.

State-of-the-art methods such as condition monitoring, video endoscopy and drone technology are used to determine the status of the wind turbine. Final reports document the current condition of the system and components and provide recommendations for action.

The following services are included in the WPK, depending on the customer's requirements:

- Document review

- Plant inspection (outside and inside)

- Scope of inspection: foundation, tower, engine house and transformer station

- Evaluation and recommendations for action

Inspection for condition-orientated maintenance (ZOP)

Insurance companies require a comprehensive inspection of all key components of a wind turbine at regular intervals. The main aim of the inspection for condition-based maintenance (ZOP) is to recognise initial damage at an early stage and thus prevent consequential damage. It is also carried out when damage is suspected, in the event of a change of ownership or to secure claims.

ENERTRAG Operations carries out the inspections according to the criteria of Gothaer Versicherung ("Principles for the inspection of condition-based maintenance of wind turbines") or according to individual customer requirements.

The ZOP includes the following services depending on the customer's requirements:

- Document review

- Inspection of the wind turbine

- Inspection of the rotor blades

- Vibration analysis of the drivetrain

- Inspection of the gearbox using video endoscopy

Inspection after commissioning (H1)

The report of the main inspection provides the system operator with a reliable basis for comparing the status quo delivered with the contractual agreements and, if necessary, demanding rectification from the manufacturer.

The inspection before and after commissioning (H1) is carried out as part of the handover of the wind turbine to the operator. ENERTRAG Operations carries out the inspection in accordance with the guidelines of the German Institute for Structural Engineering (DiBt).

The following services are included in the H1 inspection before and after commissioning, depending on customer requirements:

- Document review

- Inspection of the wind turbine

- Rotor blade inspection prior to installation can be offered as an option

Customer benefits

- Services according to the latest state of the art in science and technology, accepted everywhere

- Highest quality level through engineer-led service delivery

- Flexible, system-specific pricing

- Support in enforcing the operator's claims

- Detailed report with deviations and recommendations for action

Inspection before the warranty expires (H2)

When financing wind turbines, operators and banks assume a term of at least 20 years. Defects from the commissioning phase should therefore be recognised at an early stage within the defined warranty period and rectified by the manufacturer. The inspection before the warranty expires helps to identify defects and subsequently assert claims against the manufacturer.

5 good reasons for an inspection before the warranty expires

- It is ensured that the wind turbines do not carry over any unidentified defects from the first few years of operation

- Warranty claims can be made to the manufacturer so that they can carry out any necessary repairs in time

- Reducing risks of increased maintenance costs after the end of the warranty

- Clients receive a reliable means of comparing the delivered status quo with the contractual agreements

- The inspection before the warranty expires can of course also be used as the first recurring inspection (WKP)

The aim of ENERTRAG Operation is to operate wind turbines as safely as possible. To ensure this goal, qualified specialists carry out inspections on wind turbines according to individual demands and requirements and in accordance with the guidelines of the German Institute for Building Technology (DIBt guideline)

The following services are included in the H2 inspection before the warranty expires, depending on the customer's requirements:

- Document review

- Checking the elimination of deviations from the test after commissioning

- Inspection of the wind turbine

- Inspection of the rotor blades (external and internal) with lightning protection test

- Vibration analysis of the drivetrain

- Inspection of the gearbox using video endoscopy

- Inspection and analysis of the transmission oil

- Inspection and analysis of the lubricant in the rotor bearings

Rotor blade inspection by drone or rope access

Rotor blade inspections are among the most complex inspection activities on a wind turbine. ENERTRAG Operation inspects by drone or rope access.

The rotor blade inspection includes the following services:

- Inspection of rotor blades (external)

- Inspection of rotor blades (internal)

- Rotor blade lightning protection test

Additional accredited inspections

- Gearbox inspection

- Lubricant removal

Safety checks

Safety is the be-all and end-all in wind turbines. This is why, in addition to other tests, annual safety inspections of certain components are required in accordance with the Ordinance on Operating Sites.

Safety inspections serve in particular to maximise occupational safety for personnel working in a wind turbine. It also makes economic sense to adhere to the annual interval for safety inspections: If, for example, it is not possible to climb the vertical ladders because they have not been checked, necessary inspections or repairs may be delayed and yield losses may occur.

ENERTRAG Operation offers the following services throughout Germany:

- Annual safety inspection:

Fixed ladder, climbing protection, crane systems, first-aid kits, rescue equipment, PPE, fire extinguishers, service lift (if applicable) - ZÜS inspection of service lift

Mandatory annual inspection of service lifts by an authorised inspection body (ZÜS). For example: Main / intermediate / possibly follow-up inspections, inspections after modifications requiring inspection (e.g. modifications to the lift / winches / safety gear) - Repairs

Any minor repairs to defects identified during the inspection can be carried out directly - quickly and easily to ensure smooth continued operation.

Further inspections

DGUV-V3 inspections

A wind turbine, the transfer station and the substation at the grid connection point are considered electrical installations and are subject to numerous regulations that operators are often unfamiliar with.

This is based on Section 49 of the German Energy Industry Act (EnWG), according to which energy systems must be set up and operated in such a way that technical safety is guaranteed. This gives the DIN VDE standards, in particular VDE 0105-100, legal force with regard to the operation of an electrical installation. Here and in Regulation 3 of the German Social Accident Insurance (DGUV), it is stipulated that the operator must have the system checked regularly by a qualified electrician to ensure that it is in proper condition. The primary aim is to prevent accidents and ensure personal safety.

However, due to the complex legal situation, experience has shown that many operators only fulfil their obligations incompletely, which can have serious consequences in the event of damage. These range from consequences under labour law to fines and even criminal prosecution.

During the legally compliant implementation by ENERTRAG Operation, several hundred criteria to be tested are processed - in the low and medium voltage range, including protective device tests. All electrical components that could be a source of danger to people and the safe and proper condition of the system are inspected, tested and/or measured.

Customer benefits

- Increased occupational safety, minimisation of liability risk

- Legally compliant adherence to legal and insurance requirements

- Flexible, customised pricing

- Standardised test report with precise measurement data and recommendations for any necessary maintenance measures as well as a new test date

Additional inspections

- Inspection of the wind turbine in terms of the duty to maintain safety

- Object-orientated risk assessment (GBU) per wind turbine type per wind farm

- Rotor blade inspection by drone incl. lightning protection measurement

Accreditation by the DAkks

ENERTRAG Betrieb GmbH is a type C inspection body accredited by the German Accreditation Body (DAkkS) in accordance with DIN EN ISO/IEC 17020 for the scope specified in the certificate annex D-IS-18273-01-00.

Status / Updated: July 2022

Co-operation partner

ENERTRAG Operation draws on an experienced network of partners to offer service packages tailored to individual customer requirements.

UL International

- leader dans le domaine de la modélisation météorologique, de la modélisation de la charge et de la certification des éoliennes - accrédité selon la norme ISO IEC 17065 - membre du comité consultatif d'experts du BWE - Certifications LTE délivrées selon ANSI UL4143 - Bureaux dans plus de 140 pays avec plus de 500 experts et 35 ans d'expérience

News

Stay up to date with the latest articles from the press area.

ENERTRAG commissions first wind turbine in Lower Saxony

ENERTRAG, one of Germany's leading renewable energy companies, is pleased to announce the commissioning of its first wind turbine in Lower Saxony near Ramelsloh (municipality of Seevetal, district of Harburg). The new turbine, a Vestas V150 with a rated output of 4.2 MW, represents an important milestone for the company in the federal state of Lower Saxony.

ENERTRAG secures medium-term investment loan to finance growth

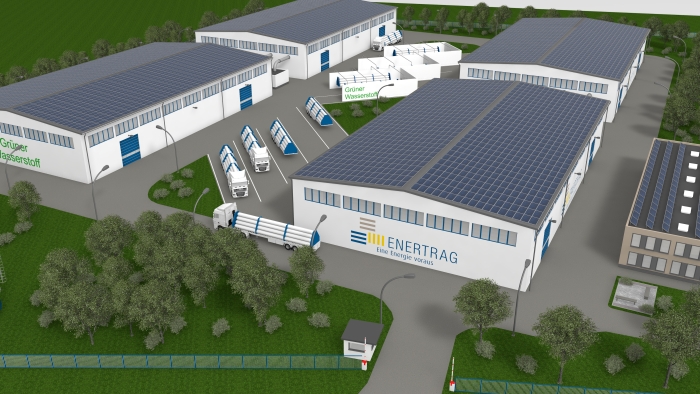

Ground-breaking ceremony for electrolyser at Osterweddingen Industrial Park

Verbundkraftwerk Anklam: A milestone for sustainable energy and regional growth

Hyphen hydrogen project in Namibia on the way to becoming a strategic foreign project of the Federal Republic of Germany

EU Commission approves funding for the ENERTRAG project "Electrolysis Corridor East Germany"

Fraunhofer IWES is setting new standards in onshore numerical site assessment in Namibia

ENERTRAG appoints Dr. Tobias Bischof-Niemz as Member of the Management Board for Projects International & Technology

ENERTRAG-Projekte Hyphen und HyShift auf der COP28 als "Energy Transition Changemakers" ausgezeichnet