Our renewable hydrogen solutions

Enertrag, Europe's hydrogen pioneer

Over the past few years, ENERTRAG has become a major player in the energy transition thanks to its wind and photovoltaic production. With a view to facilitating their integration into the grid, we decided in 2009 to develop the production of renewable hydrogen in order to make the most of electricity production, while at the same time contributing to the decarbonization of other sectors, such as industry and mobility. Our hydrogen is produced by water electrolysis. This process extracts hydrogen and oxygen from the water molecule, using electricity generated from 100% renewable resources.

Our H2 solutions

Thanks to the feedback we've received from our projects around the world, we're now in a position to offer tailor-made, turnkey projects to meet the needs of local authorities wishing to develop a mobility ecosystem based on renewable hydrogen, as well as industrial companies looking to decarbonize their business.

Mobility

Developing low-carbon mobility

As the transport sector is the biggest emitter of greenhouse gases in France, we need to act quickly to limit emissions. In this respect, renewable hydrogen may be the preferred solution, as no greenhouse gases are emitted during vehicle use, nor are there any fine particles responsible for local air pollution.

Industry

Decarbonizing the industrial sector

Many industries such as glassmaking, refining and ammonia production (needed for fertilizers) currently use hydrogen produced from fossil fuels. We therefore offer all these industries, and others that could potentially use hydrogen in their processes, renewable hydrogen production solutions, adapted to each need and at a competitive price.

Energy storage

Storing energy with hydrogen

Last but not least, hydrogen is set to play a major role in the integration and balancing of renewable energies on the grid in the years to come. Thanks to Power to Gas, it is possible to store electricity in the form of hydrogen, and to restore this stored electricity at a later date, for example during peak periods. To this end, we offer electricity storage solutions using hydrogen as a vector.

Our hybrid power plant

In 2011, we commissioned Europe's first hybrid power plant to convert 6 MW of wind power directly into hydrogen. The hydrogen is then either used for mobility purposes or injected directly into the local natural gas network for industrial use.

Our skills

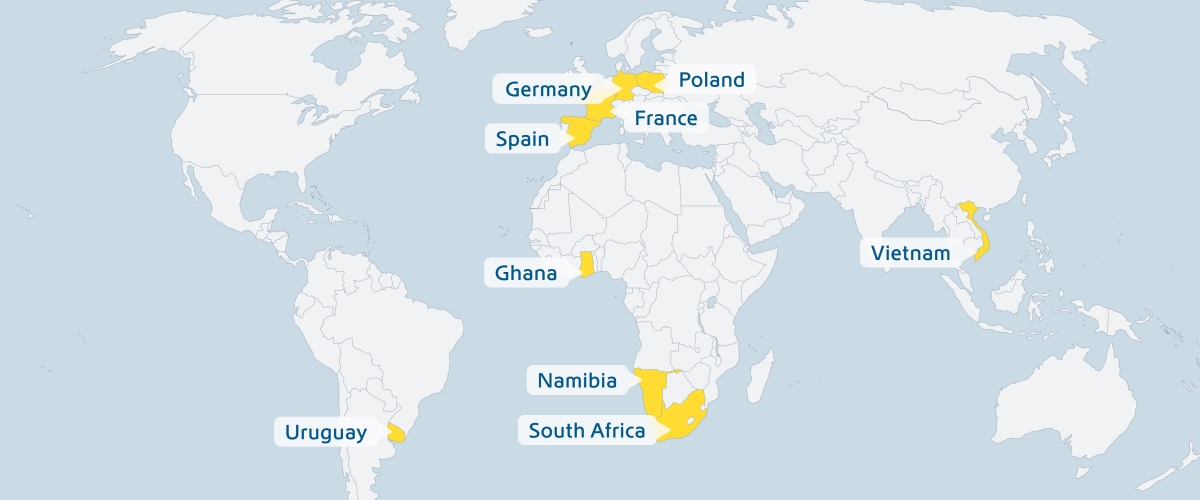

Our references

The regional train

- 6 FCEMU trains covering a distance of 1.3 million km/year

- A 3 MW electrolyzer producing around 200 tonnes of H2 per year

- 5 MWe of wind power and 4 MWp of PV to cover all H2 production needs

- The consumption of around 610,000 liters of fuel oil is avoided per year, representing 2,500 t of CO2.

Synthetic fuel

- Conversion of CO2 emissions from cement production to produce synthetic fuel using a Fischer-Tropsch process, recombining CO2 and H2

- 20 MW SOEC electrolyzer

- 30 Mwe of wind power and 30 MWp of PV

- For production of around 5,000 tonnes of naphtha per year

Kerosene production

- Conversion of CO2 emissions from the chemical industry to produce synthetic fuel using a Fischer-Tropsch process, recombining CO2 and H2

- 200 MW electrolyser

- 400 MW of renewable energies

- For production of around 50,000 tonnes of Kerosene per year