Park operations

ENERTRAG has been managing the technical and commercial operation of wind farms in France for over 15 years, both on its own behalf and on behalf of third parties. While the latter was historically handled by the German head office, since 2014 it has been managed by our French team. Operations encompass the technical, regulatory and commercial management of wind farms.

Our supervision and inspection center

Supervision

The mission of our wind farm supervision department is to ensure that the wind turbines are running smoothly, and to record any faults and failures on our Powersystem online platform. Our operators are in regular contact with the technicians and the various people working on the wind farms. They record the types of intervention and list the work and breakdowns carried out. The team works closely with the operations managers to discuss any situation that requires it (park decoupling, loss of communication between the machines and the supervision center, degradation, etc.). Our supervision centers provide a 24/7 remote monitoring service for all our parks in operation.

Inspection

Visual inspections

The team of inspectors carries out periodic visual inspections (once or twice a year) of all wind turbine components (exterior/interior), quality control of the machine and the proper performance of maintenance services by the companies in charge. Non-conformities are recorded on the Powersystem application during the inspection. The team then draws up a report with recommendations for action, based on the information gathered during the inspection. We also carry out this type of on-site inspection during the commissioning of a wind farm (review of OEM non-conformity lists).

Drone blade inspections

In less than 30 minutes, our qualified remote-controlled inspectors can carry out a complete diagnosis of your blades independently, and detect any defects or damage. ENERTRAG Exploitation carries out these inspections on all the most common turbine models. For our Enertrag fleet, we carry out this type of blade inspection by drone twice a year. Following the inspection, the inspection team draws up a report analyzing the defects, and also recommends the repair work to be carried out, along with the timeframes for implementation.

What sets us apart

Production optimization

ENERTRAG is responsible for the technical and commercial management of wind farms throughout their operating life. Our experience in managing these facilities enables us to optimize turbine availability, electricity production and the analysis of performance indicators. We also keep a technological watch on new solutions on the market that are relevant to our customers, in order to improve or extend wind farm performance.

Our customers

We produce monthly and annual reports and presentations of results to help our customers manage their operating strategy. We also discuss the validation of operations requiring investment.

Turbine operators

We liaise with turbine operators to monitor maintenance, regulatory controls, breakdowns and major component changes, and to ensure compliance with maintenance contract clauses.

The dreal

We provide the DREAL with all information and documents justifying the regulatory compliance of our wind turbines in operation.

France renouvelables

We take part in working groups organized by the France Energie Eolienne business association, during which we work on improvements and solutions to problems encountered by the wind power industry, in collaboration with other operators.

Permanent control

Thanks to a remote control system developed by ENERTRAG (PowerSystem), our engineers scrutinize and analyze data from every plant in operation, 24/7. They receive essential data in real time, such as energy production, wind conditions or the status of each wind turbine. This constant monitoring enables us to detect any malfunction and react as quickly as possible. There are many reasons for machine stoppages: mechanical failure, electrical faults, software faults, network faults and safety faults are the main ones. Turbines may also be shut down for preventive maintenance or environmental reasons.

The operating team remains on call in the event of decoupling, loss of communication between supervision and the park, or fire, for example.

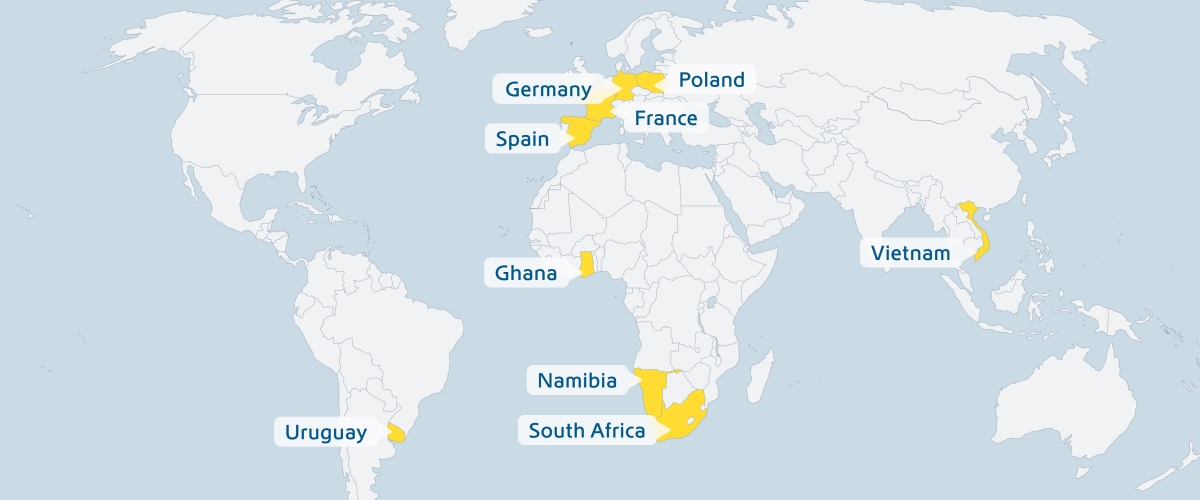

ENERTRAG, your partner at every stage of your project. A single point of contact throughout the project to facilitate communication and ensure the successful completion of your project.

ENERTRAG operations certified iso 9001-2015

In 2020, ENERTRAG's operations department was awarded ISO 9001-2015 quality certification. It demonstrates the department's ability to consistently deliver a service that meets customer requirements, applicable legal and regulatory requirements, and its commitment to increasing customer satisfaction. This certification is a lever for optimizing internal operations, controlling activities, detecting market signals, reducing costs and boosting competitiveness.