Safety checks

This documentation provides an overview of the scope of services.

Safety is the be-all and end-all in wind turbines. For this reason, in addition to other tests, annual safety inspections of certain components are required in accordance with the Ordinance on Operating Sites.

Safety inspections serve in particular to ensure the highest possible occupational safety for personnel working in a wind turbine. It also makes economic sense to comply with the annual interval for safety inspections: If, for example, it is not possible to climb the vertical ladders because they have not been checked, necessary inspections or repairs may be delayed and yield losses may occur.

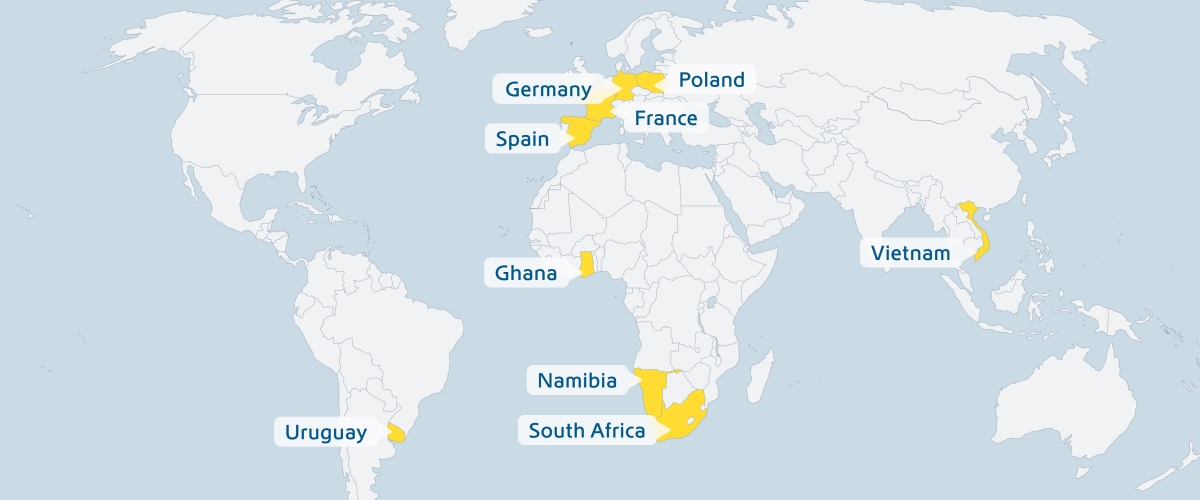

ENERTRAG Betrieb offers the following services throughout Germany:

Annual safety inspection:

Fixed ladder, climbing protection, crane systems, first-aid boxes, rescue equipment, PPE, fire extinguishers, service lift (if applicable)

ZÜS inspection of service lift:

Mandatory annual inspection of service lifts by an approved inspection body (ZÜS). For example: Main / intermediate / possibly follow-up inspections, inspections after modifications requiring inspection (e.g. modifications to the lift / winches / safety gear)

Repairs:

Any minor repairs to defects identified during the inspection can be carried out directly - quickly and easily to ensure smooth continued operation.

Safety is the key to success - especially in wind turbines! Regular safety inspections are not only required by law, they also protect lives and prevent your turbine from costly downtime. With professional inspections, our team ensures that your wind turbine runs reliably and safely. In the following interview, our experts answer the most frequently asked questions about safety inspections and repairs - in a practical and understandable way.

Hydraulic components in wind turbines are subject to extreme pressure cycles.

We test your pressure accumulators, pressure vessels and associated components – non-destructively, in accordance with standards and reliably.

Why pressure testing is important in wind turbines

Hydraulic systems are used in every wind turbine. These systems consist of pressure accumulators, vessels, valves, pipes and pumps and are exposed to high stresses due to pressure peaks and cyclic load changes. More than 1,000 pressure peaks per day are not uncommon in some systems.

Without regular testing, there is a risk of material fatigue, irreparable damage or even failure of critical components. Such failures are not only costly, but can also pose safety and environmental risks.

Our scope of services

Together with a ZÜS (approved monitoring body), we carry out recurring inspections in accordance with the Industrial Safety Regulation (including § 16 BetrSichV).

Our inspections cover the entire system:

• Pressure accumulators / pressure vessels

• Valves, pumps, pipes

• Seals and connecting elements

• Safety devices (e.g. pressure relief valves)

We use state-of-the-art non-destructive testing methods (e.g. ultrasound) to detect internal material defects and wall thickness deviations.

Advantages for operators

• Increased operational safety and reduced risk of failure

• Standard-compliant documentation and certification

• Early detection of damage – targeted maintenance measures possible

• Longer service life of hydraulic components

Flyer on the safety checks of ENERTRAG Operation

Safety pays off - let us work together to ensure that your system runs smoothly. Protect your employees and maximize the efficiency of your wind turbine. Get in touch with our team today to schedule your next safety inspection. Our experienced experts are always available to help!

Safety inspections are not just a regulation - they are an investment in the future of your turbine. Only through regular inspections can you ensure that all components are working properly and accidents are avoided. You can also prevent unnecessary downtime and expensive repairs through preventive maintenance. Protect your profits and the lives of your employees - with the right precautions!