Technical management of wind farms

Technical management

Technical management by ENERTRAG means transparent reporting, ongoing yield optimisation and condition-based maintenance:

Every minute, the ENERTRAG Operation control centre monitors and evaluates the operating and condition data of the systems. 24 hours a day, seven days a week - as if the ENERTRAG experts were on site around the clock. Customers benefit from bundled expertise from other specialist departments, which creates the greatest possible synergies. The aim is to maximise the energy availability of the systems.

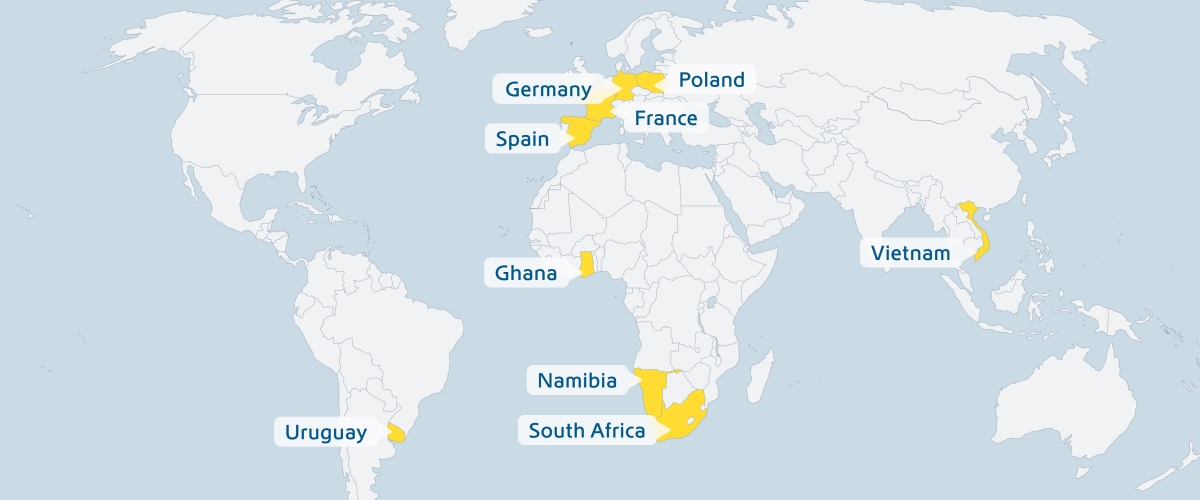

ENERTRAG technical management is divided into three teams: Technical Operations Management Germany, Technical Operations Management International and Support. This ensures a holistic but also focussed view for customers. Thematic priorities can also be set which are transparent and comprehensible for everyone.

Operations Management Services

News

Stay up to date with the latest articles from the press area.