Concrete Chemicals

Support programme Guidelines on State aid for climate protection, environmental protection and energy (KUEBLL)

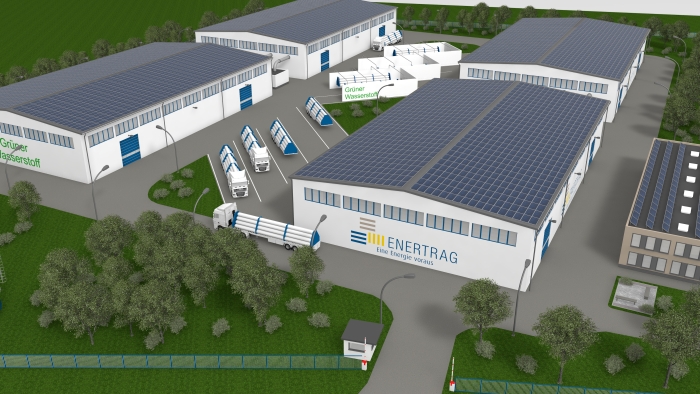

The flagship project Concrete Chemicals is regarded as the first milestone in the decarbonisation of the cement industry. The strong project partners from industry and research – including the renewable energy company ENERTRAG, the global building materials manufacturer CEMEX and Sasol ecoFT, a leader in the development and application of Fischer-Tropsch (FT) technology – are paving the way towards more climate-friendly cement production by converting CO2 into renewable chemical products and synthetic fuels.

The EU has set itself ambitious targets to overcome the challenges of climate change: Politicians and industry are aiming for a climate-neutral economy by 2050. As part of the cement industry, CEMEX is also pursuing the ambitious goal of reducing its CO2 emissions and becoming climate-neutral by 2050 at the latest.

Rüdersdorf

The cement plant in Rüdersdorf is one of the most efficient plants in Europe. Not least for this reason, the global building materials manufacturer CEMEX has chosen this location to test and promote innovative technologies to achieve climate neutrality. The technological findings from the Rüdersdorf ‘Carbon Neutral Alliance’ are to be gradually applied in all CEMEX cement plants and adapted to the respective local conditions in order to accelerate the achievement of climate targets by decarbonising the entire cement production process. CEMEX has set itself the goal of transforming the plant in Rüdersdorf into the first climate-neutral cement plant by 2030.

Project profile

| Location: Rüdersdorf |

| Performance class: PtL plant for the production of synthetic aviation fuels, 40 kt/a |

| Commissioning: Q3/2028 |

| H2 quantities: ca. 18.000 t/a |

| Supply concept: H2 pipeline and on-site generation |

Objectives

The project partners have set themselves the goal of developing and using highly innovative and recyclable catalytic material systems to enable the production of green hydrocarbons from industrial waste gas emissions. In particular, the utilisation of CO2, but also CO and H2, will ensure that the overall efficiency can be increased by 50 percent compared to previous processes.

In addition, the consortium is driving the development of innovative catalytic processes fuelled by renewable energy to produce climate-neutral raw materials on an industrial scale. In this way, the cost efficiency of the technology can be demonstrated while using less critical materials.

About ENERTRAG

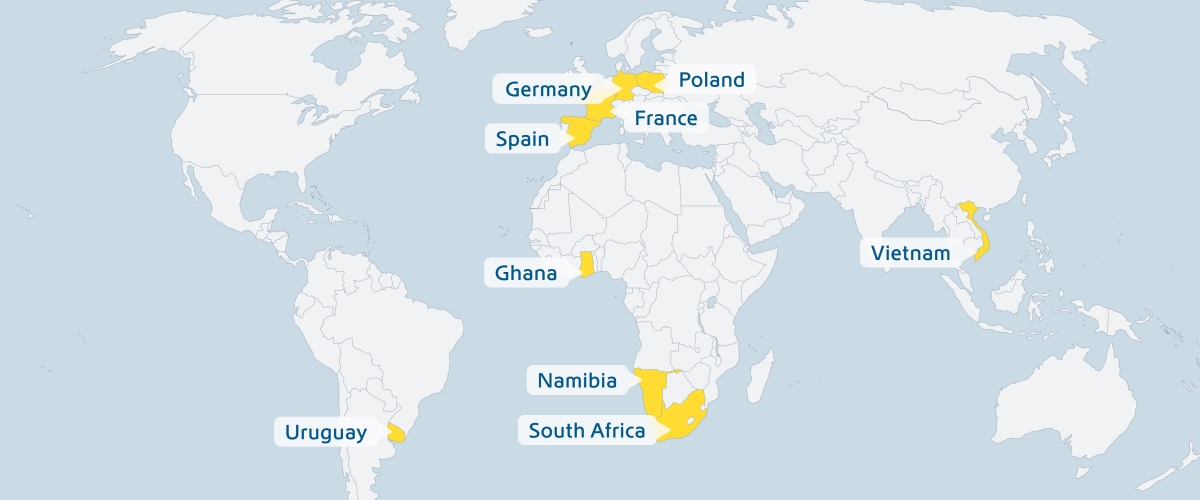

As an independent energy company, ENERTRAG generates electricity and heat exclusively from renewable sources and supplies secure, affordable renewable energy for all areas of life. With over 30 years of experience, ENERTRAG combines all the expertise required for successful operation and efficient maintenance, for citizen-centered planning, reliable construction of energy plants and grids through to complete integrated power plants.

News

Stay up to date with the latest articles from the press area

ENCAVIS acquires wind farms from ENERTRAG in Bonnhagen and Roitzsch

ENERTRAG relies on strong leadership: new input in engineering and implementation

ENERTRAG and Ingka Investments to explore repowering in Germany

N-ERGIE relies on ENERTRAG: Partnership for the use of the power system for technical operations management and 24/7 monitoring

Procurement reforms critical to accelerating SA's renewable energy rollout

ENERTRAG and the town of Prenzlau conclude contracts for financial participation in wind turbines

ENERTRAG Announces Appointment of Enos Banda as CEO of its South African business

Connecting to a constrained grid

ENERTRAG opens office in Hamburg: New momentum for green hydrogen economy

ENERTRAG Expands Its Management Board with a New Position

Empowering women in energy: A step towards transforming leadership in South Africa

ENERTRAG South Africa's commitment to societal development and sustainable energy transition

ENERTRAG joins aireg as a member

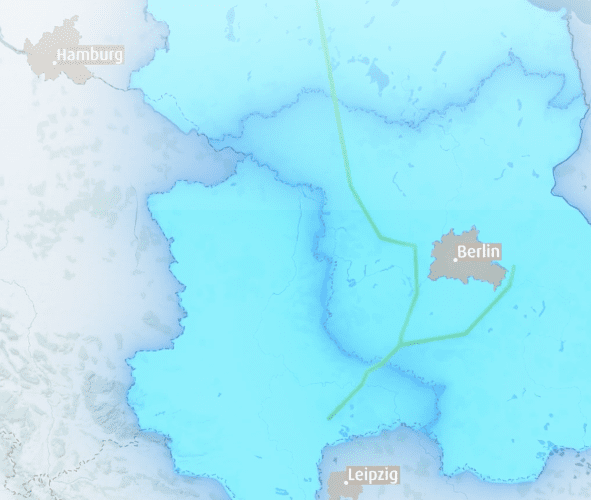

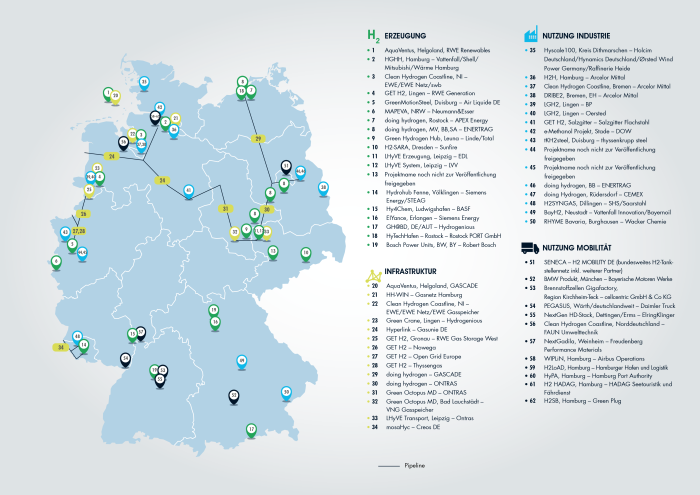

Handover of the funding notification for the ENERTRAG project "Electrolysis Corridor East Germany"

ENERTRAG celebrates record year 2023/24 in project development

ENERTRAG eröffnet neues Büro in Kiel

ENERTRAG commissions first wind turbine in Lower Saxony

ENERTRAG secures medium-term investment loan to finance growth

Ground-breaking ceremony for electrolyser at Osterweddingen Industrial Park

Verbundkraftwerk Anklam: A milestone for sustainable energy and regional growth

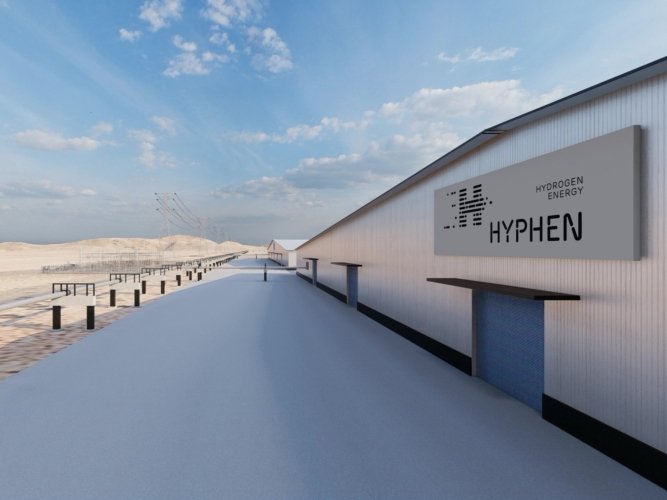

Hyphen hydrogen project in Namibia on the way to becoming a strategic foreign project of the Federal Republic of Germany

EU Commission approves funding for the ENERTRAG project "Electrolysis Corridor East Germany"

Fraunhofer IWES is setting new standards in onshore numerical site assessment in Namibia

ENERTRAG appoints Dr. Tobias Bischof-Niemz as Member of the Management Board for Projects International & Technology

Full (solar) power ahead: ENERTRAG Operation takes over operations management of 20 MW large-scale photovoltaic project

ENERTRAG selects Elogen for the delivery of a 10 MW PEM electrolyser

Right in time for operators: ENERTRAG Operation offers drone inspection in France by 2023

ENERTRAG Operation offers drone inspection as a licence model by 2023

ENERTRAG inaugurates 186 MW Dunowo wind project in Poland

Dr. Gunar Hering to become new ENERTRAG CEO

Consistently high standards: ENERTRAG Powersystem is again certified according to ISO/IEC 27001 and DIN EN ISO 9001

ENERTRAG plans green hydrogen project in the Tacuarembó region of Uruguay

Concrete Chemicals on the way to climate-friendly cement production and CO2-neutral flying by using green hydrogen

ENERTRAG Operation further expands business in France

ENERTRAG et Orange Pologne concluent un contrat d’achat d’électricité (Power Purchase Agreement).

ENERTRAG and Orange Polska secure a long term PPA in Poland

Parution du Numéro 17 l’ENER’MAG

ENERTRAG becomes European: Conversion to SE completed

Colombian Energy Minister Diego Mesa visits ENERTRAG

Uruguayan delegation visits ENERTRAG and receives first-hand information about the potential of green hydrogen.

ENERTRAG enters the Spanish market for renewable energies and establishes a joint venture with TeXla Energías Renovables

International consortium launches green hydrogen project to decrease the cement industry’s CO2 footprint

ENERTRAG poursuit son développement en région Bourgogne-Franche-Comté

ENERTRAG enters second IPCEI tender round with 210 MW electrolysis plant

Green Areal Lausitz (GRAL): Euromovement and ENERTRAG sign cooperation agreement to implement a CO2-neutral energy concept