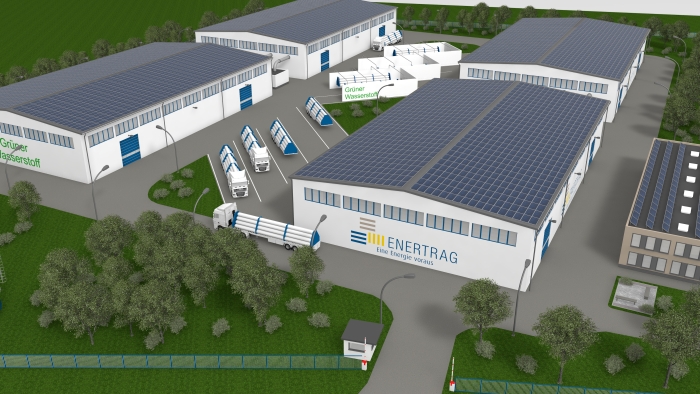

ENERTRAG Powersystem

Software for smart operations management of renewable energy systems – modular, clear, secure.

Powersystem lets data speak for itself

The Powersystem is the professional software solution for renewable energies. It saves time and money when operating PV and wind energy systems and helps to recognize opportunities and risks at an early stage.

The software offers many different functions: from reports to options for controlling the systems to the minute. ENERTRAG also stays on the ball and is constantly developing solutions for new regulatory requirements. Everything from a single source.

Benefits

- Optimized operation and smart networking of renewable energy systems

- Better performance for more power in less time

- Monthly upgrades according to regulations

- Agile, highly rated user support

- Development experience since 1999

- Automated condition monitoring

- Certified quality and data security

- Suitable for critical infrastructures

- High data quality thanks to control of our data stream control center

More accurate and efficient: How apps and drone-based inspection procedures are revolutionizing the wind industry.

Certified quality

The ENERTRAG Powersystem software stands for reliable quality and data security and is suitable for the operation of critical infrastructures in accordance with KritisV.

Quality management according to ISO 9001:2015

The certification proves that ENERTRAG SE fulfils all the requirements of the relevant standard (DIN EN ISO 9001:2015), works in a process-oriented manner for the development and provision of software and IT infrastructure and has established risk-based thinking.

Risk Management according to ISO/IEC 27001

With this certification, ENERTRAG SE demonstrates commitment to the continuous improvement, development and protection of information assets / sensitive data through the implementation of appropriate risk assessments, policies and controls. The scope of the certificates is operational management, remote monitoring, EisMan billing, feed-in billing, remote controllability and power control.

News

Stay up to date with the latest articles from the press area.